Hardness Measurement

Hardness defines the resistance to local deformation of a material when indented, drilled, sawed, or abraded. It involves a complex combination of properties (elastic modulus, yield strength, strain-hardening capacity). The prevailing deformation mechanism depends upon the material and the type of tester. Hardness is either measured by static penetration of the specimen with a standard indenter at a known force, dynamic rebound of a standard indenter of known mass dropped from a standard height, or scratching with a standard pointed tool under a load. The hardness tester, indenter shape, and force employed strongly influence the hardness numbers.

Hardness is used in identification, classification, and quality control. Hardness tests provide a rapid evaluation of variations in mechanical properties affected by changes in chemical or processing conditions, heat treatment, microstructure, and aging. Since the hardness test usually produces an insignificant permanent change in the specimen, it is considered to be a non-destructive test.

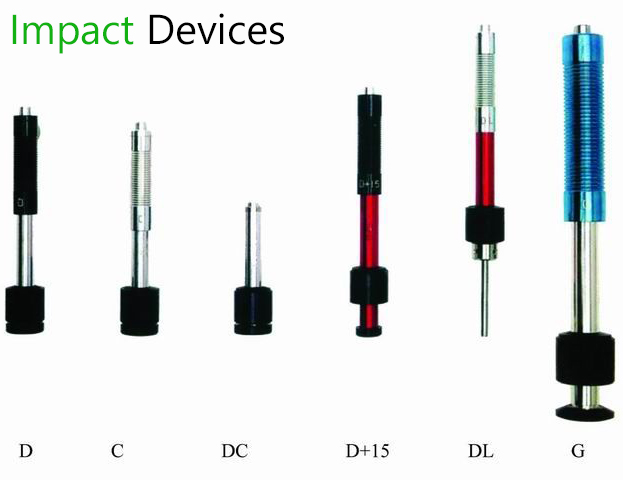

An impact device fires an impact body containing a permanent magnet and the very hard indenter sphere itself towards the surface of the test material. The velocity of the impact body is recorded in three main test phases;

Leeb’s genius idea was to measure the velocity of the impact body contact-free via the induction voltage generated by the moving magnet trough a defined induction coil mounted on the guide tube of the device. The induced voltage is directly proportional to the velocity of the magnet, thus, the impact body containing the magnet. The induced induction signal is recorded in an electronic indicator device and the peak induction voltages are further processed to give Leeb’s hardness number, the L-value.

WRITE TO US

Quality Network Pvt Ltd.

Works

No. 10, II Cross Street, Kalaimagal Nagar,

Ekkattuthangal, Chennai - 600032

CONTACT US

Registered Address

#38/GA, Shoreham, 5th Avenue, Besant Nagar,

Chennai – 600 090

CONTACT DETAILS

Phone: +91 44 3551 0355