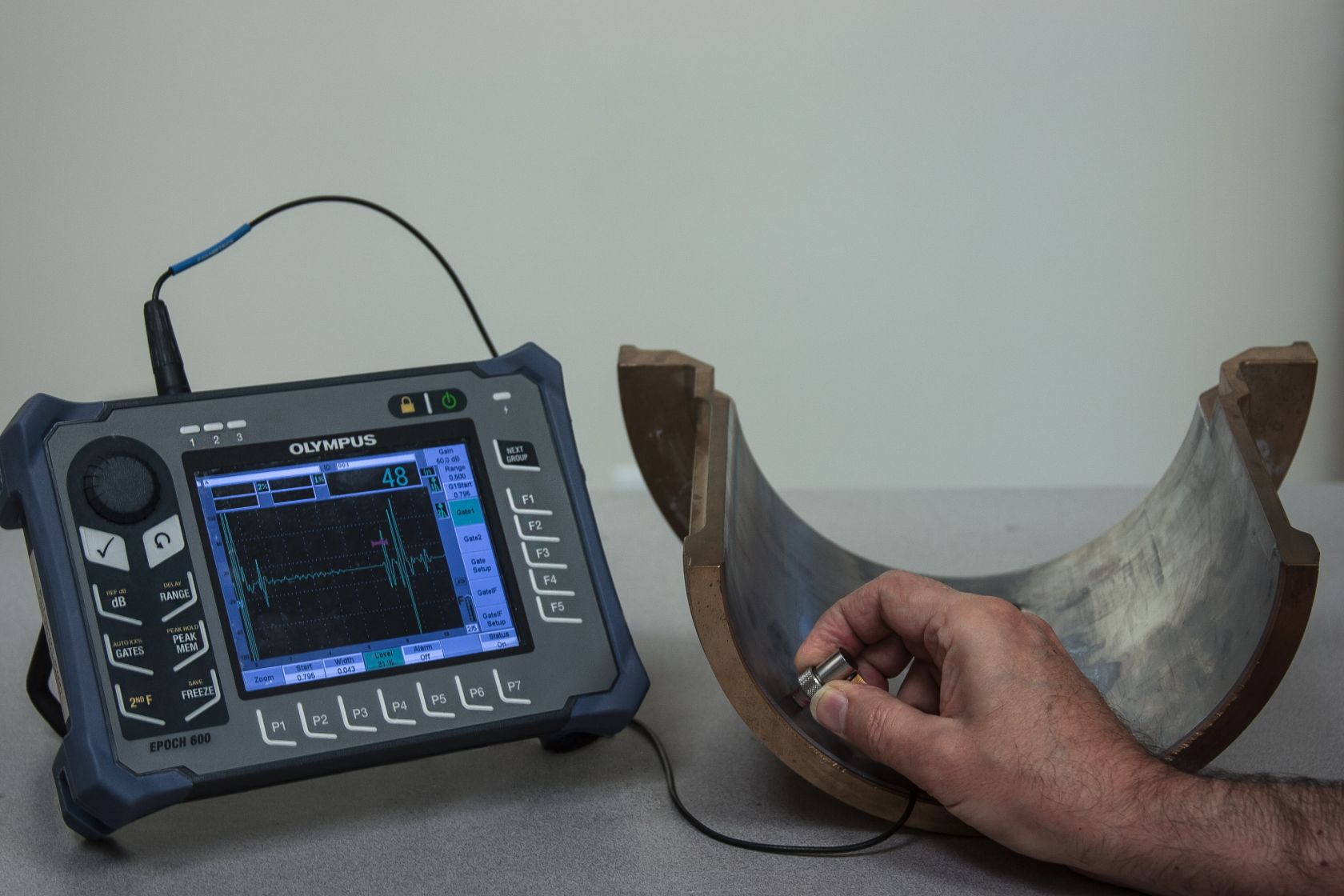

Ultrasonic Flaw Detection

Ultrasonic flaw detection is a powerful NDT technology and a well-established test method in many industries.

Sound waves, which are all around us, are simply organized mechanical vibrations traveling through a medium, which may be a solid, a liquid, or a gas. This applies to both the everyday sounds that we hear and the ultrasound used for flaw detection. Sound waves will travel through a given medium at a specific speed or velocity, in a predictable direction, and when they encounter a boundary with a different medium they will be reflected or transmitted according to simple rules. This is the principle of physics that underlies ultrasonic flaw detection. In short, ultrasonic waves will reflect from cracks or other discontinuities in a test piece, so by monitoring the pattern of echoes in a part a trained operator can identify and locate hidden internal flaws.

Applications include

WRITE TO US

Quality Network Pvt Ltd.

Works

No. 10, II Cross Street, Kalaimagal Nagar,

Ekkattuthangal, Chennai - 600032

CONTACT US

Registered Address

#38/GA, Shoreham, 5th Avenue, Besant Nagar,

Chennai – 600 090

CONTACT DETAILS

Phone: +91 44 3551 0355