Magnetic Particle Testing

Magnetic particle examination is a very popular, low-cost method to perform non-destructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as “a term applied to materials that can be magnetized or strongly attracted by a magnetic field.” MT is an NDE method that checks for surface discontinuities but can also reveal discontinuities slightly below the surface.

Different Techniques

There are many different techniques and combinations of techniques of MT. The ASME Boiler and Pressure Vessel Code, Section V, Article 7, recognizes five different techniques of magnetization:

There are two different ferromagnetic examination media: dry particles and wet particles. Both forms can be either fluorescent or non-fluorescent (visible, color contrast) and come in a variety of colors to contrast with the tested material.

How Magnetic Particle Examination Works

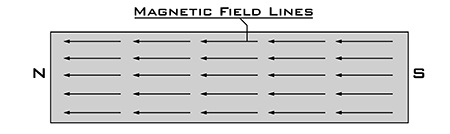

When ferromagnetic material (typically iron or steel) is defect-free, it will transfer lines of magnetic flux (field) through the material without any interruption.

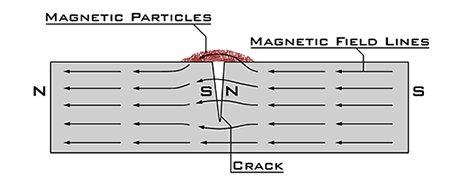

But when a crack or other discontinuity is present, the magnetic flux leaks out of the material. As it leaks, magnetic flux (magnetic field) will collect ferromagnetic particles (iron powder), making the size and shape of the discontinuity easily visible.

However, the magnetic flux will only leak out of the material if the discontinuity is generally perpendicular to its flow. If the discontinuity, such as a crack, is parallel to the lines of magnetic flux, there will be no leakage and therefore no indication observed. To resolve this issue, each area needs to be examined twice. The second examination needs to be perpendicular to the first so discontinuities in any direction are detected. The examiner must ensure that enough overlap of areas of magnetic flux is maintained throughout the examination process so discontinuities are not missed.

Typical Examples of ASME Code-Required Inspections

In the ASME codes of construction, magnetic particle examination or liquid penetrant examination is specified many times to detect the possibility of surface defects. If material is nonmagnetic, the only choice is liquid penetrant examination. However, if material is ferromagnetic, magnetic particle examination is generally used. Some typical examples of ASME Code-required inspections include, but are not limited to:

Once boilers and pressure vessels are in service, MT can be a widely-used examination method. MT may be used for the inspection of items such as:

WRITE TO US

Quality Network Pvt Ltd.

Works

No. 10, II Cross Street, Kalaimagal Nagar,

Ekkattuthangal, Chennai - 600032

CONTACT US

Registered Address

#38/GA, Shoreham, 5th Avenue, Besant Nagar,

Chennai – 600 090

CONTACT DETAILS

Phone: +91 44 3551 0355